Click on the images below to play another video

Digipor is an innovative system for decoration of polystyrene packaging with new digital concept. Thanks to our experience in digital printing systems and automations and the big experience in production of polyester material of our OEM partner, our know how in this type of application is very high. A new philosophy in polystyrene packaging decoration is to give more visibility and more value to your business; in-fact the visibility of brand is one of the most important voice in a marketing investment and in this direction we can drive you! Our research department invested more than one year for the development this type of application and worked in partnership with a chemical industry to create a special hybrid inks dedicate to polystyrene with high a great color gamut, with bright colors, wash and water resistant and most of all with a new non-toxic formulation. Thanks to this we are able to print directly on polystyrene with high quality and speed with infinity possibility of images to print!

We are in patent for this application that is new in a world, like the concept of movement of the materials and the type of applications with more than 20 different code inside. Digipor is a new possibility on the polystyrene expanded packaging box market to give more value to it and also to increase the turn over of productions. Digipor is a concept application with a digital printer inside and dedicated RIP software to create your job and line control. Thanks to Digipor-RIP we can control all the functions of line with a user-friendly interface to work 24h/day.

Digipor can be made in 4 different configurations: Digipor Static, Digipor EASY, Digipor 1, Digipor 2 to have a full total range of possibility. The most important characteristic is the output volume, in-fact Digipor can print a line of packaging in about 40 seconds (+/-) in automatic way.

Static line for EPS printing with print width 700 or 1300mm, print lenght customizable from 2500 to 5000mm. This industrial EPS digital printer feature also a removable square on all the lenght, a print thickness up to 450mm, a new rip&print professional software WhiteRIP and a tablet for remote control of the printer.

Print area size: up to 1300x5000mm

Thickness: from 0 to 450mm

Semiautomatic line for one side with automatic packaging feeder, loading area, printing station, raccording area to dryer station, dryer station, unloading area with 5 units of magazine, control area with touchscreen panel.

Max. print size: 620 x 500 mm

Thickness: from 50 to 550 mm

All the configurationes use the some tecnology, software and hardware dpi-ser.Tec edition, all the descriptions is described on the general technical date

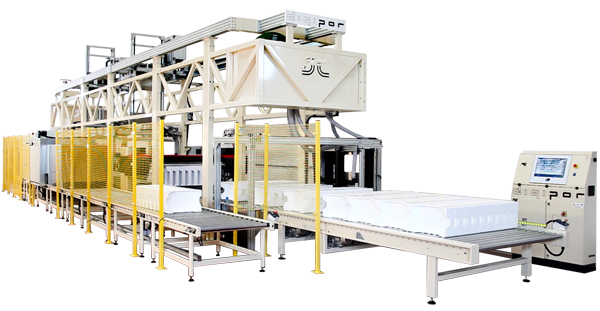

Line automatic for one side with automatic feeder,loading zone,preprint area,printing station,raccording area to dryer station,dryer station,unloading area with magazine untill 10 packaging box,one control area with touch screen and flat-video

Max. print size: 1200 x 500 mm

Thickness: from 50 to 650 mm

Full line completly automatic with feeder, loading zone,pre - print area, 1 printing station,raccording area to dryer station, 1 dryer station,roller feeder to 2 printing station,turnable station of packaging, 2 printing station, raccording area for 2 dryer station,2 dryer station .Unloading area with magazine untill to 10 packaging box,2 different control area with touch screen and flat-video

Max. print size: 1200 x 500 mm

Thickness: from 50 to 650 mm

Line configuration and layout is customizable based on customer request.

Marketing video of tecnology is included for your marketing action with license to use and show.