Overview

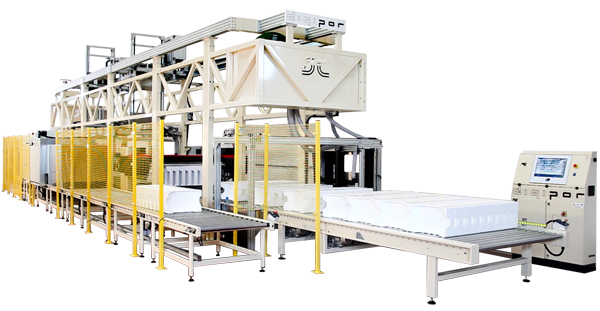

Digipor is an innovative system for decoration of polystyrene packaging based on a new digital concept.

Thanks to our long experience in digital printing systems and industrial automation, combined with the strong

know-how of our OEM partner in polyester material production, Digipor represents a highly specialized solution

for this type of application.

The new philosophy behind Digipor is to give more visibility and more value to your packaging.

Brand visibility is one of the most important elements in marketing investment, and Digipor is designed

to enhance it directly on EPS packaging.

Our R&D department invested more than one year in the development of this technology, working in partnership

with a chemical industry to create special hybrid inks dedicated to polystyrene.

These inks offer a wide color gamut, bright colors, wash and water resistance, and a new non-toxic formulation.

This allows high-quality, high-speed direct printing on polystyrene with unlimited image possibilities.

Digipor is protected by patent and introduces innovative concepts in material handling and application processes,

with more than 20 different application codes. It represents a new opportunity in the expanded polystyrene

packaging market to increase product value and production turnover.

The system integrates a digital printer and dedicated RIP software for job creation and full line control.

With Digipor RIP, all functions can be managed through a user-friendly interface designed for 24/7 operation.

Digipor is available in four configurations:

Digipor Static, Digipor EASY, Digipor 1 and Digipor 2,

covering a complete range of production needs. Depending on configuration, Digipor can print a full packaging

line in approximately 40 seconds in automatic mode.